A well-installed, good quality ground or air source heat pump will require very little maintenance and should last for at least 20 to 30 years.

To ensure proper functionality, it is advisable that you have your installation checked annually either by a qualified engineer or installer or by the system’s owner.

Your supplier/installer should provide you details pertaining your heat pump’s exact maintenance requirements, and how its maintenance can be optimised.

If you own a heat pump, here are maintenance tips that will prove handy in guaranteeing continued performance.

Contents

- 1 Key Takeaways

- 2 Air Source Heat Pump Maintenance

- 3 Ground Source Heat Pump Maintenance

- 4 Heat Pump Warranties

- 5 Case Study: Comprehensive Maintenance for Longevity and Efficiency of Heat Pumps

- 6 Expert Insights About Heat Pump Maintenance

- 7 Heat Pump Source: Reliable Heating and Cooling Solutions

- 8 Conclusion

Key Takeaways

- Ground and air source heat pumps are durable and can last 20 to 30 years with minimal maintenance, but annual professional checks are recommended for optimal performance.

- Air source heat pumps require cleaning fans, checking airflow, and insulating electrical contacts. In contrast, ground source heat pumps need checks on components like the compressor, water pump, and coolant mixture.

- Most heat pumps come with a 5 to 10-year warranty on labour and parts, but with proper maintenance, they can last even longer, and some include free annual services.

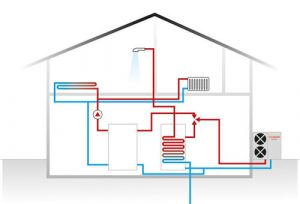

Air Source Heat Pump Maintenance

If you own an air source heat pump or are looking to acquire one, you will be glad to know that this particular system requires very little on-going maintenance. While each air source heat pump is different, there aren’t very many differences when it comes to maintenance. Manufacturers still advise owners about what their systems require in regards to seasonal or annual maintenance.

As an air source heat pump owner, here are some maintenance tasks you can perform to ensure that your system operates as intended:

- Clean fans and foils (if need be)

- Swap out or clean filters

- Clean the system’s supply

- Ensure air flow is not blocked by debris (dust, leaves, etc.)

- Power off the system and clean/check the fan blades

- Return registers inside the property

Before winter (or summer if you use your heat pump for cooling), it’s recommended that you have the unit checked and serviced by an air source heat pump expert. Experts conduct a more comprehensive audit of the system’s components and are better placed at identifying issues that could degrade a heat pump’s performance which users wouldn’t spot or diagnose. These checks involve the following:

- Checking refrigerant pressure and levels

- Checking ducts for leakage and repairing them if need be

- Measuring airflow to see if it is correct

- Inspecting ducts, indoor coils, filters and blowers for dirt and other debris that could hamper air flow

- Checking for system leaks

- Checking all electrical contacts and ensuring that they’re well insulated

- Lubricating motors, moving belts and checking for wear and tear or damage

- Checking reverse cooling/heating controls and ensuring they’re operating as required

- Checking and testing thermostat under normal operating conditions

Unlike other types of renewable energy technologies like wind turbines and solar PV which use expensive inverters, air source heat pumps generally don’t require the replacement of costly parts during their lifespan.

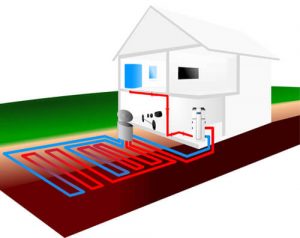

Ground Source Heat Pump Maintenance

Ground source heat pumps use the same operation principle as refrigerators only that they work in reverse, which makes maintenance limited. However, a majority of ground source heat pumps will require annual checkup by a professional technician to ensure that they are operating within their tolerances as under performing heat pumps could lose up to 25 per cent of their efficiency in both operating energy consumption and under performance. Please note that if the system’s thermostat is set very low, this could cause the system to kick in the rather expensive auxiliary heater. As a result, the unit will use more than the normal amount of energy it needs to operate.

Various ground source heat pump manufacturers will specify a unit’s recommended service and maintenance schedules in their documentation. So, before you buy a unit, it is advisable that you do some research into which heat pumps offer the most reasonable maintenance requirements. Search for other people’s comments and recommendations concerning particular units to get an idea of the system’s performance and dependability. Also, remember to ask questions regarding the unit’s you are considering to ensure you get the best.

If you own or plan to get a closed loop heat pump, these are the main components that need checking:

- The compressor – if it fails, the entire thing will have to be replaced as it’s a sealed unit

- The control equipment and electronics

- Above ground pipes and connectors

- The water pump – which is the only movable part of the system

- The bleed system, radiators, and system fluid

- Coolant/anti-freeze fluid in the ground array – it is advisable that you check if the chemical mixture is correct

It is worth noting that devices designed to contain or containing F-Gas refrigerants can only be worked on by “F” gas certified engineers. Additionally, if you want a large commercial heat pump, keep in mind that larger commercial systems are subject to stricter maintenance requirement.

A majority of ground source heat pumps are designed to last for more than 25 years, with most continuing to operate without a hitch well beyond this period. Since ground source heat pumps have very little components making up the system, this type of renewable heat generation is providing to be one of the best and most efficient heating methods currently.

Heat Pump Warranties

A majority of ground and air source heat pumps come with a five to ten-year warranty on labour and parts as standard. However, if well-maintained, your heat pump could last much longer than this (even 20 to 40 years.) Most heat pumps also come inclusive of free annual services; however, not all installers and manufacturers offer this provision.

Case Study: Comprehensive Maintenance for Longevity and Efficiency of Heat Pumps

Background

A residential client reached out to Heat Pump Source for a comprehensive maintenance check on their air source heat pump, which had been in operation for five years. The client had noticed a gradual decline in heating efficiency and wanted to ensure the system was in optimal condition before the winter season. The heat pump had been relatively low-maintenance, but regular professional inspections had not been conducted since installation.

Project Overview

The primary objective was to perform a detailed inspection and maintenance service to restore the heat pump’s efficiency and prevent potential breakdowns during peak usage. The scope of work included both routine checks and preventive measures to enhance the system’s longevity.

Implementation

Inspection and Diagnostic Process

- Visual Inspection: Our team began with a thorough visual inspection of the unit, checking for any visible damage, debris accumulation, or signs of wear and tear on the exterior and interior components.

- System Performance Analysis: We assessed the system’s performance by measuring the airflow, checking the refrigerant levels, and ensuring that the thermostat was functioning correctly. The goal was to identify any discrepancies that could indicate inefficiencies.

Maintenance Actions

- Filter Cleaning and Replacement: The air filters were cleaned and replaced as needed, ensuring that the system could operate without obstruction and maintain good air quality.

- Fan and Coil Cleaning: The outdoor fan blades and coils were cleaned to remove dust and debris, which can impede the heat exchange process. This cleaning is crucial for maintaining efficient operation and preventing strain on the system.

- Electrical System Check: We inspected all electrical connections and controls to ensure they were secure and functioning correctly. This step included checking the insulation of electrical contacts to prevent potential short circuits.

- Refrigerant Level Check: The refrigerant levels were checked and adjusted to the manufacturer’s specifications, ensuring efficient heat transfer and system performance.

- Duct and Vent Inspection: The ducts and vents were inspected for leaks and blockages. Any identified issues were addressed to ensure optimal airflow and system efficiency.

Results

- Restored Efficiency: The maintenance actions taken resulted in a noticeable improvement in the system’s heating efficiency, with the client reporting better performance and consistent indoor temperatures.

- Prevention of Future Issues: By addressing minor issues early, we prevented potential major breakdowns, ensuring the system would operate reliably throughout the winter season.

- Extended System Lifespan: The comprehensive maintenance service helped prolong the lifespan of the heat pump, providing the client with peace of mind and protecting their investment.

Summary

This case study underscores the importance of regular maintenance for heat pumps to ensure their longevity and efficiency. At Heat Pump Source, our expert team conducted a thorough inspection and maintenance service that not only restored the client’s heat pump to optimal performance but also helped prevent future issues. Regular professional check-ups are crucial in maintaining the reliability and efficiency of heat pumps, ensuring they provide sustainable and cost-effective heating solutions for many years. This project highlights our commitment to delivering high-quality HVAC services tailored to the specific needs of each client.

Expert Insights About Heat Pump Maintenance

Regular maintenance is key to ensuring that your heat pump operates efficiently and lasts for its full lifespan. Simple tasks like cleaning filters and checking for debris around the unit can significantly improve performance and reduce energy consumption.

HVAC Maintenance Specialist

Annual professional check-ups are crucial for identifying potential issues before they become major problems. These inspections can help maintain optimal performance and efficiency, preventing costly repairs and extending the life of your heat pump system.

Senior Service Engineer

Heat pumps, whether air source or ground source, are reliable and durable systems. However, understanding and following the manufacturer’s recommended maintenance schedule is essential for keeping the system running smoothly and efficiently.

Technical Director

Heat Pump Source: Reliable Heating and Cooling Solutions

At Heat Pump Source, we take pride in our unwavering commitment to serving the UK with top-tier HVAC solutions. From the efficiency of heat pumps and the cool relief of air conditioning to the warmth of boilers, radiators, and underfloor heating, our dedicated team is always at the forefront of innovation. We understand the unique needs of every household and business, and we strive to provide dependable health and cooling products and services that are tailored just for you. Ensuring your comfort and satisfaction is our utmost priority. Whether you have questions, need guidance, or require support, we’re always here to assist. Please don’t hesitate to contact us; we’re eager to be of service.

Conclusion

Investing in heat pumps, whether ground or air source, is a long-term commitment that promises durability and efficiency for decades. While these systems are designed to require minimal maintenance, the importance of annual professional check-ups cannot be overstated. These routine inspections ensure the system operates at its peak, safeguarding against potential inefficiencies and prolonging the unit’s lifespan. With the added benefit of warranties and potential free annual services, heat pumps are a reliable and sustainable choice for heating solutions.

About the Author

At Heat Pump Source, our articles are the product of a collaborative effort among a team of highly skilled HVAC experts. Our dedicated professionals, hailing from diverse backgrounds in heating, ventilation, air conditioning, and refrigeration, contribute their extensive knowledge and experience to every piece of content. This multidisciplinary approach ensures comprehensive coverage. Our commitment is to deliver authoritative, reliable, and tailored advice to meet the unique needs of every household and business across the UK.